Tools and Supplies Needed

-

Excellent ventilation. Excellent ventilation.

Dope is extremely toxic. Imagine having a

big jar of fingernail polish open under your nose for a couple hours.

A charcoal mask is a very good idea.

-

Clear Nitrate or Butyrate

dope.

Some people say that nitrate dope has better adhesive qualities than

butyrate. I don't know if that's true or not but I've had no problems

using butyrate for the entire job. Nitrate isn't fuel proof so if your

plane is glow powered then you should use butyrate dope exclusively after

the covering is attached.

Butyrate dope can be applied over nitrate but nitrate can not go over

butyrate. Once you being using butyrate you must continue with it.

-

Dope thinner.

-

A Jar having a lid with a

liner that isn't affected by dope.

Dope solvent is very hot and will eat through

foam or rubber cap liners from food jars. If you can't find a jar

having an appropriate cap then you can always put a piece of aluminum foil

over the jar before screwing on the lid.

-

Flat 1/2" and 1" natural hair

paint brushes or an airbrush with a large nozzle.

-

Acetone for clean up.

-

Paper towels.

-

Sanding block with very fine

paper.

Dope is much too thick as it comes and must be thinned to brush well.

Find a jar with a cap having a liner that the dope won't melt. An 8

ounce jar is large enough to not need constant refills but small enough to

work with.

Fill the jar about 1/3 full of dope. Thin it until it's a

good brushing consistency. I usually start with an equal quantity of thinner

and adjust from there. If it's too thin then add more dope. If

too thick then add more thinner. Don't use retarder in the sealing

coats.

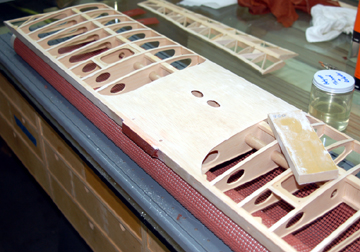

Sealing the Wing

An

airbrush with a large nozzle can be used to apply sealer coats and will

save you a lot of time. It may require several more coats as the coats

will go on thinner than if you brush. A Paasche Type H with the large

tip is perfect for this. Keep in mind that an airbrush is the wrong

tool to dope the overall wing. See the linked page for an explanation.

- Only use natural hair brushes to brush dope. Synthetic brushes

work poorly when applying dopes and lacquers.

-

All sealing coats are brushed on one side of the wing. When the

first side is dry the other side is coated. Three brushed coats are

usually all that

are necessary.

-

Exposed end grain wood should have additional coats added any time you're adding

any other coat. For example, if the wing tip has end grain then coat

it when you coat one side of the wing and then coat it again when you coat the

other side of the wing.

-

Seal any hatch compartments, holes or

anything else water or fuel may be able to work its way into. If your

wing has center section sheeting then it may draw water into the end grain

from the wet silk. Run the brush around exposed end grain and holes

that the silk covers with each coat.

If the wing ribs are not capped or sheeted then doping them (or getting

them wet) will raise the wood grain. What that means is that if you

dope silk over unsealed ribs there will be a lot of ugly bumps under the

silk that are there forever. Be sure to seal the edges of the ribs

well.

Sand lightly between coats to remove any raised grain and make everything

smooth. Sand as little as possible so that you aren't sanding back

down to bare wood. Sand lightly between coats to remove any raised grain and make everything

smooth. Sand as little as possible so that you aren't sanding back

down to bare wood.

Keep applying thin coats of dope until the grain doesn't raise. Now

apply a heavier coat of dope that is thinned to brushing consistency.

This dope should not be as thin as the dope you've been using up to now.

Sand after this coat. Keep applying these coats until you can sand

without exposing bare wood.

I normally need to brush on two coats of very thin dope and then one or

two coats of normally thinned dope.

Don't get stuck on the number of coats. If you apply thinner coats

than I do you may need more. It's not the number of coats that's

important. It's that the wood is actually sealed and wood grain isn't

raised. If you can't tell if an area is sealed then run a wet finger

over it. If the wood grain raises or the wood feels slightly mushy

then it's not sealed. Allow the wood to dry, sand it lightly and

recoat.

You can apply a final coat if you like. It won't hurt anything and

clear dope weighs practically nothing.

Vacuum the wing when you're satisfied with the sealing coats. If

you have an air compressor then blow out the wing and vacuum it again.

The wing is now ready to silk as soon as its mounted on something that

prevents the wing from moving around and allows the silk to hang straight

down all around the wing. |

![]()