|

Always sand the entire panel, not just the area that doesn't

match. For example, this photo clearly shows the leading edge is

not the same on both panels. We could just sand the leading edge in

the root area until the panels match, but the edge is probably wrong along

the entire length of the panel.

Use a long

sanding block, such as a T-Bar, to sand along the entire leading

edge.

Again, work slowly and check your work frequently. Be sure to

carefully align the wings on the

building board as if you were going to

glue them together. |

|

This photo was taken immediately after the one above.

It looks like the leading edges match well but nothing has changed from

the photo above. Note that the sheeting on one panel is

slightly higher than the sheeting on the other panel.

While this could be left alone because it won't cause problems from

an aerodynamic point of view, it will make it more difficult to finish

the wing.

If the panels are off significantly then there is no question that

you should spend some time on them using a sanding block. |

|

I spent over an hour working on the two panels

individually (taken apart) to bring

them to a close match. Remember, we aren't actually working on

just the center, but the entire wing. I frequently fit the

panels back together to check my progress.

Before the

panels are actually glued together, I dry fit them and work out a

jigging system to ensure everything is ok and that the panels will

stay in the correct position while the glue dries.

I already did this several times when I was sanding

the wing root in the previous installment

of this article. |

|

The panels are a very close match, the leading edges are

the correct shape and I'm a happy guy. |

|

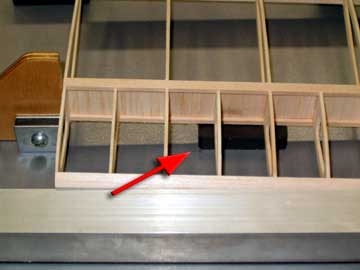

The

magnet shown here is propping up the wing panel. You can prop

up the panel anywhere you like as long as the tip is the correct height

off the board. Another magnet is used for the opposite wing

panel. It is in an exact mirror image location as the magnet for

this panel. |

|

Joining the wing panels properly is extremely important.

I could just prop up the tips to the correct height, eyeball the center

sections and leave it at that. I don't care for

this practice because on more than one occasion I've had the panels

shift while the epoxy cured. The only fix was to saw the panels

back apart.

It's better just to do it right in the first place by jigging the

panels so that they stay in the correct position until the glue is dry.

This wing is a rectangular planform so a straightedge at the

leading or trailing edge will ensure the wings align properly.

Some instructions indicate that one panel should be flat on the board

and the other panel is propped up. While that works in theory,

what can sometimes happen in practice is the propped up panel slides

down which creates a strange center section. As long as the panel

is propped up to the correct height and the panels aren't twisted, you

can use the method if you prefer.

My preference is to prop up both panels. I think it gives a

better end result. |

At this point you can permanently join the wing panels if you are

satisfied that everything is correct and that you have a way to keep the

panels aligned while the glue dries. Put a piece of wax paper

under the center of the wing so the wing isn't glued to the board or the

plan.

Do not join wings using fast-setting glues such as cyanoacrylate or

5-minute epoxy

I use 30 minute or slower epoxy to join wing panels. Having time is

something I especially appreciate when an operation is critical.

Straight wings fall under this category.

Smear a thin coat of epoxy on both root ribs. Take some time

to work it into the grain. A thick coat of glue is not necessary or

desirable. Butt-joins are inherently weak and more glue won't improve

the situation, but will make sanding much more difficult later.

If the wing has a dihedral brace then you can join the panels in your

hands and then put them on the board.

Coat both sides, the top and the bottom of one half of brace.

It is a good idea to also coat whatever the brace contacts inside the wing

panel if you can reach it.

Slide the brace into one panel and then coat the other half. Slide

the second panel on the brace. Pay attention to the brace to ensure it

doesn't slide too far into the first panel. Push the panels together

firmly. Wipe up excess glue using paper towels and alcohol.

You'll be glad you did this.

If the wing does not have a dihedral brace then you'll have to join the

panels on the board unless you have a helper to hold the panels together

while you wipe up excess glue. Ensure that there isn't too much glue

on the root ribs because it will squeeze out from the bottom of the joint

where you can't get to it to wipe it off.

Put all the jigging back in place after the panels are on the board.

In the photo above you can see two

magnetic upright fixtures placed at the spar ends. These fixtures

are applying clamping pressure to the wing center section. You can

also use heavy weights such as cinder blocks, car batteries or

whatever you happen to have.

Measure everything immediately. Ensure the two panels are not

twisted. Check that the wing tips are propped to the correct dihedral.

If you find that you simply can't get everything aligned properly then it is

best to take everything apart and wipe off all the epoxy using alcohol.

If this happened then you skipped one or more steps of preparation.

Assuming that everything is correct, leave the wing to cure thoroughly

before removing it from the board. If the wing does not have glass

cloth wrapped around the center then all you need to do is some final

touch-up sanding and the join is finished. |

![]()