Use sewing machine oil or another

light oil to thoroughly coat every part while the engine is disassembled. The

parts don't need to be

dripping oil, but they do need to be coated. Sewing machine oil is

safe for all parts of all engines that I am aware of.

|

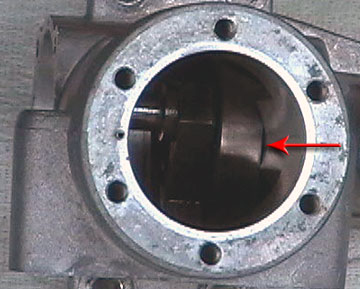

The crankshaft and bearings must be in place before

anything else. Shown here are the rear ball bearing (not all engines

have ball bearings) and an aluminum spacer having a purpose I have no idea

about. But I know where it goes, so I don't need to know what it

does. The rear bearing is not sealed. It can go in facing

either direction. |

|

The rear bearing and spacer in place on the crankshaft. |

|

The front ball bearing is sealed on one side. The

sealed side faces out to keep dirt from entering the bearing and the

engine. Shown here is the unsealed side of the bearing. |

|

The sealed side of the front bearing. Again, not

all engines have ball bearings. Economy engines often have bronze

bushings that should not be removed. |

|

The crankshaft is inserted into the engine through the

backplate opening. The bearing is a tight fit and unable to seat.

To remove the bearing, the engine was heated in the oven.

Aluminum

expands more than steel so heating the engine allows the bearings to

fall out.

The reverse is also true. Heating the engine

allows the bearings to go back in place which was what was required

here. I put the crankcase in a 250°

oven for about 10 minutes. Only the crankcase was placed in the

oven — not the crankshaft and bearing. |

|

After heating the case the front bearing falls into place

easily. The sealed side is out. |

|

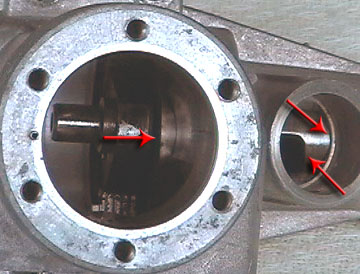

Heating the case allows the rear bearing to slide into

place more evenly. However, you can see that it is not fully

seated.

When the crankshaft is seated properly the opening in the crankshaft will align with

the carburetor hole or at least be much closer.

To remedy the

situation, I put the thrust washer on and then bolted a propeller to the

engine. Tightening the propeller nut pulled the crankshaft and

rear bearing into place. |

|

The piston, wrist-pin and connecting-rod. Note the

cutout on the skirt of the piston. This cut-out goes forward and

prevents the piston from contacting the rear bearing. In some

cases there is a relief at the back of the piston to prevent it from

contacting the backplate or the rear bearing. This is why you need to examine your

engine before disassembling it. Putting parts in backwards is easy

to do.

Note that the connecting rod has two different size holes. This

ensures that the right end is in the piston, but it can still be turned

around backwards. This engine, for example, requires the connecting

rod to face a certain direction. If it is backwards, the engine

will not turn over. Each engine is unique, so this may not be the

case with yours. |

|

The assembled piston. Note the oil hole in the bottom of the

connecting rod. |

|

The piston goes into the engine before the liner. If you put the

liner in first, you will not be able to put the connecting rod over the

pin on the crankshaft. |

|

The engine is shown here upside down. Most frequently, the pin on

the crankshaft has to be at its top position in order to put the

connecting rod on the crank-pin. |

|

The connecting rod seated properly on the crankshaft pin. |

![]()