|

|

|

|

How

to Disassemble a Model Aircraft Engine

Before you consider disassembling an engine you should have a very

good reason. Every time an engine is taken apart there is the risk of

doing more harm than good.

Likewise, if you don't have a very good reason to disassemble the

carburetor then leave it alone — even if you disassemble the rest of the engine.

Leave the needles alone because you don't want to change the settings

if you don't have to. The only reasons for taking an engine apart

are:

- An internal component is damaged such as a broken connecting rod.

- A part is worn and needs replacement such as bearings or the piston

and liner.

- The engine was crashed and dirt got inside (very unlikely).

- You are curious and it is worth the risk of damaging it to see what's

inside.

- You are writing a how-to article for your website.

|

|

|

|

Taking the Engine Apart

Note: Information contained in the instructions supersedes

information presented here. Be sure to review the parts diagram and

instructions that came with your engine before taking it apart.

Remove the engine from the aircraft. Use a stiff bristled brush to remove as much dirt from the outside of

the engine. If you have an air compressor then it works well to blow

dirt from the engine. Gather up necessary tools, a couple clean rags, a can of

light machine oil, a container to put small parts in and another container filled with

whatever cleaning solution you plan to use. I normally use

denatured alcohol.

This article will not cover cleaning the engine, but if you want to do

that, then a good method is shown

here.

Important! Never use any type of metal

tool or object inside the engine.

Be sure to make a small scratch

on the head and the cylinder before you take it apart so you know how it goes back on. Do the

same thing with backplate.

|

|

|

|

|

A few items needed to take the engine apart. Lay out

a clean rag and use a second rag to wipe oil from the parts. A

toothbrush is helpful for removing varnish (cooked engine oil). A hardwood dowel is

useful for a couple of purposes that will be discussed later. |

|

Begin by removing major items such as the air filter,

muffler, carburetor, propeller, prop nut and washer, thrust washer and the glow

plug. Put small items in a container so they don't get lost.

Do not put items from inside the engine in the container. You don't want to scratch the piston, liner, crankshaft or anything else that

needs to have a smooth, precision surface. |

|

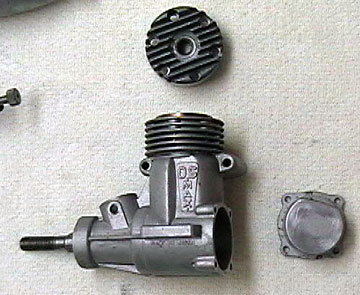

Remove the head and backplate. Normally there are more bolts

for the head than the backplate. Put the bolts in the container.

If the head and backplate have the same number of bolts and they are

different sizes, then be sure to note which are which so you can put

them back in the proper location. There is a good possibility that the

backplate gasket will tear when taking the engine apart

— particularly

if the engine has a lot of hours on it. Making a new one is

simple.

How to make a

backplate gasket When the head has a gasket it is usually made

from thin metal. Put the gasket somewhere safe so that it doesn't get bent or

damaged. |

|

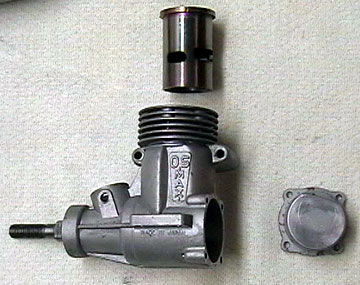

Often there is an alignment pin in the top of the cylinder that is

used to key the liner. If not, then mark the liner and cylinder so

that it can be reassembled facing the exact same way.

Most engines are designed to have the liner removed

before the piston can come out. If the liner will not slide out,

then push on it from underneath with the dowel.

If it still will not come out, then put the engine in a 300° oven for

about 10 minutes. The aluminum will expand from the heat and the

liner will slide right out. The heat will also melt varnish which

could be making the parts stick together. |

|

|

|

|

Important!

Before removing the piston, look at it from the top and through the

backplate opening. Often the connecting rod has an oil hole in it and

goes on one way.

After the engine has been run, the piston is mated to the cylinder and

should go back in facing the same direction. If it is turned around,

the engine will lose compression and wear out faster.

|

|

|

|

|

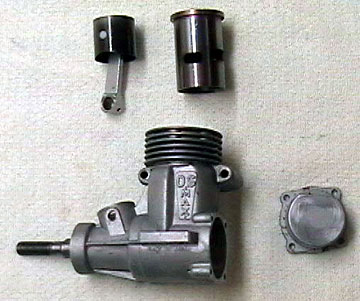

Typically the piston needs to be as high as possible to

be removed. Turn the crankshaft to move the piston up. To

remove the piston, tilt then engine backward and pull the connecting rod

from the crank pin. Turn the engine upside down and let the piston

fall into your hand.

Don't remove the piston ring unless you plan to replace it.

Some pistons have small circlips holding the pin in place.

If you want to remove the pin, then use a pair of needle-nose

pliers to carefully remove the circlip. Put it someplace safe

because the engine is out of service until the clip is replaced if it gets lost. |

|

If the crankshaft does not slide out, then set the back

of the engine on a piece of wood. Put another piece of wood over

the crankshaft and tap it lightly with a rubber mallet. It should

come out easily. If it does not then 10 minutes in the oven should

loosen it up. Some engines have a key holding the thrust

washer. These engines must have the thrust washer pulled off first

with a bearing puller. The key is then removed and then the

crankshaft.

My O.S. 1.08 is like that. I pounded on the crankshaft for

several minutes before looking at the parts diagram and realizing that

no amount of hammering was going to knock the crankshaft out until the

key was removed. Live and learn.

|

|

Usually the ball bearings do not come out easily.

Find a wooden dowel that will can be inserted through the back of the

engine and push the front bearing out. Again, heating the engine

makes removal easier. The rear bearing is removed by rapping

the engine against a piece of wood. If the engine is heated it

should fall right out.

The engine is now ready to be cleaned, have parts replaced or

whatever work done that is necessary.

|

|

|

|

|

|

|

|

|

Back to Model Aircraft Engines

Airfield Models Home |

|

|

|

Copyright © 2003 Paul K.

Johnson |

|

|

![]()