Using

the Hinge Sandwich Technique with Robart Hinge Points

I chose not to use the stock tail surfaces for my Miniplane. Although there

is nothing wrong with them, the plane needs additional

tail weight because I elected to use a larger than recommended engine. I

also do not

like the thick surface outlines.

I built surfaces having a 1/8" core with

1/16" x 1/4" ribs and outlines made from three laminations of 1/16" balsa.

The new surfaces are slightly stronger and heavier.

I have used this hinging technique on several models, including the tail

surfaces and ailerons for

Hammerhead.

This method guarantees that the hinges will be perfectly centered along the

hinge line.

-

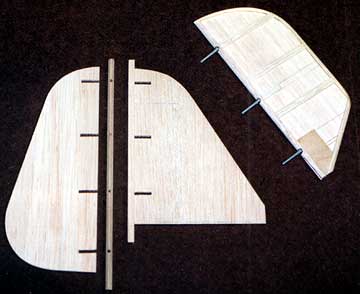

Begin by cutting the outline of the surface(s) you want to hinge.

Hinge slots for the control surface and fixed surface can be cut at the same

time to ensure they align perfectly.

-

Use double-stick tape to attach the

control surface to the fixed surface such that the leading edge of the control surface is over the

trailing edge of the fixed surface.

-

Draw a pair of lines to mark each hinge locations. The

lines should be spaced the diameter of the Hinge Point. It is best to

locate the hinges at existing rib locations. The ribs will enclose the

hinge slots.

-

Taking leading and trailing edges into account, mark the maximum depth to

which the hinge will be inserted. It is better to

cut the slots too shallow rather than too deep. The holes can be drilled deeper later

if necessary. If the holes are too deep then you will add weight and waste

glue by filling the void.

-

Cut the slots

with a hobby knife or a scroll saw. Alternatively, the parts can

be pushed through a

table saw with the part standing perpendicular to

the table and the blade raised to the depth of the slot. Use a

miter gauge to push the parts through.

Note that the leading/trailing edges are

drilled to match the cutouts. On the right is a finished stabilizer half

with the ribs in place. The ribs cap the slots and hinging is finished.

|

![]()