|

I skipped another step. You may think that you see

uprights in this photo but you actually don't. You're either

imagining things or maybe you can see into the future. What you

should see is a plywood sanding template. Cut a piece

of scrap plywood that aligns perfectly on all sides. Take

measurements from the plan to ensure the angles are correct.

Take care making the template because it will determine how well the

joints of the uprights and diagonal bracing will fit. |

|

Make a

sanding block having faces that are all square to each other.

I used 3/4" square pine.

Use

spray glue to attach medium (220)

sandpaper to one side and fine (400) paper to the other.

Note:

This sanding block will come in handy for all kinds of

purposes, so don't think of it as a limited use item.

Place

the upright brace against the side of the template and gently

sand the one end.

Balsa sands away at a much faster rate than plywood so the template should easily last

through the project. If you happen to sand too much of the

template away, correct it before sanding any more braces. |

|

Fit the sanded end of the upright to ensure the angle is

correct. Lightly mark the other end with a single-edge razor blade.

Use the template to sand the end of the brace to fit. Be conservative and

leave the brace over-length at first. Sand a little away at a

time. Fit often.

The bracing should be a good fit — not too snug and definitely

not loose. |

|

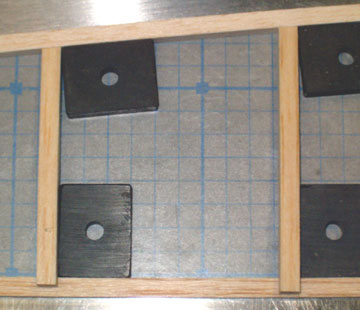

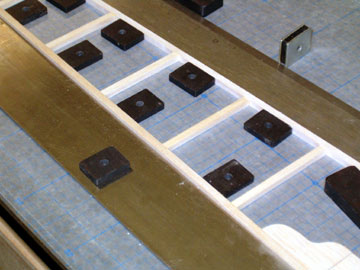

Here you can see several upright braces glued into place. |

|

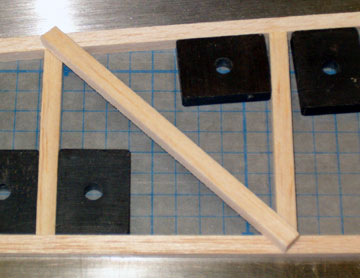

The template you made will make short work of

this task and for a change, the diagonal braces will actually fit properly.

Cut the piece over-length as shown. Lay the brace over the

fuselage side aligning it with the plan.

I normally ignore the plan and instead align the brace so that it centers on the corners made by

the upright and longeron. |

|

Carefully align the razor over the longeron and existing upright

and use it to lightly mark the bevels.

You do not have to mark directly above the joint. In fact, it's

best to mark slightly over-size.

It is important that the

angle of the cut lines exactly match the corner in relation to the

centerline of the diagonal piece. Read that a few times until it

makes sense. |

|

Place the diagonal brace over the correct corner of the

template ensuring that the marked lines are aligned properly with

the template and that the end of the brace is centered over the template

corner. |

|

Sand the end to shape. Although I didn't do it, a piece of sandpaper spray glued to

the template would have helped prevent the diagonals from sliding around while

I was sanding. |

|

At this point only one end is sanded to shape but look at

both ends. The opposite end should

be too long but should center over the existing joint.

If the other end isn't centered properly then note which way

the diagonal must rotate.

Take the diagonal back to the template to correct it.

When you are satisfied with the first end, mark it with pencil so that you know

which side is up and which end is which. It's easy to flip the

part around when adding glue or whatever. Once glue is on the

ends, it is more difficult to tell which end is which. |

|

Repeat the above steps for the other end. Note

that if the fuselage has straight outlines, but also tapers, then the

angle on the ends will always be the same on braces that are aligned in

the same direction.

However, the diagonal braces are not parallel to each other and

therefore the angle on the end will not be at the same angle to the

centerline of the brace.

I know that sounds confusing, but once you start making these pieces

you'll understand what I mean. My point is that you can't stack up

all the diagonals and cut them at once. They won't fit if you do

that. |

|

If the diagonal is still too long then you can make

adjustments while sanding away the excess. Always use the

template. If

the length of the diagonal is correct, but one end or the other doesn't fit

properly then

there's not much you can do. Your choices are to live with it or try

again with a new part.

This was my first time using a template and I only had to discard two

parts. I have a higher reject ratio using a disk sander and a much

higher reject ratio making braces when cutting and sanding by hand. |

|

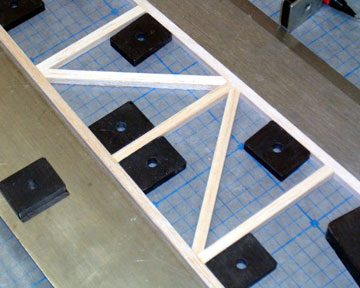

This is how the diagonal should fit. The diagonal

slips in place easily but is not too loose and not too snug.

Do not force a tight brace into position. It will create

undesirable internal stresses and may weaken the longeron by crushing

the wood fibers. It will also be forcing the glue joint apart of

the upright braces. |

|

Double-glue the ends of the

braces using carpenter's glue. Put some glue on each end

and set the part aside for a minute. Put some glue in the existing

joint as well. After giving the glue some time to soak into the

end grain, add a little more glue and put the part in place.

Ensure everything is flat on the board while the glue dries.

Make a scooper from a toothpick or bamboo skewer by

cutting a long bevel on the end. Use it to scoop up all the glue

that oozes out.

Your work will look especially neat now that you have made perfect

fitting joints using nicely sanded pieces and there is no visible glue. |

![]()