Home Made Sanding Blocks

Flat Sanding Blocks

I have dozens of sanding blocks if you count the little

sanding sticks I make, but only a few of them get frequent

use. My most

used blocks are cut from 1/2" medium density fiberboard (MDF).

Each block is double-faced with the same grade of paper. I have a dozen of

three different sizes of

these blocks ranging from 50 to 400 grit sandpaper.

Another block I use is made of oak that is 3/4" thick. I sanded it flat

on both sides and glued a piece of 1/16" neoprene to one side to soften it

slightly. That is the face I use most often. On the other face is a

piece of 1/2" black foam rubber that is relatively firm. I use that face

for compound curves such as fuselages and wingtips.

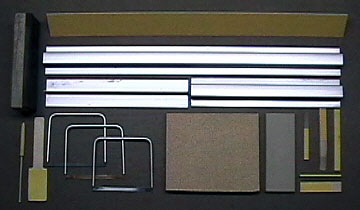

A variety of sanding blocks

|

Top left —

An oak block with 1/16" neoprene on one side and 1/2"

firm foam rubber on the other.

Top right —

Four

T-Bar sanders.

Bottom row from

left to right

Small dowel wrapped with sandpaper.

Paddle-sander.

Flex-I-Files bow sanders

—

Excellent for plastic models and hard to reach areas of any

model.

1/2" MDF fiber board sanders faced on each side with

sandpaper. These are the blocks I use to sand sheet balsa tail

surfaces.

Various purpose made sanders for sanding spar notches, etc. |

|

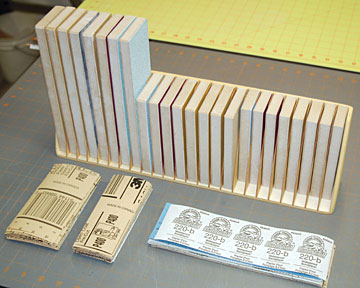

These are my general use sanding blocks prepared to get new

paper. Each block is made from 1/2" MDF and is double-faced with the

same grade of sandpaper. I clamp the block in a bench vise and use

a heat gun and spatula to remove the old paper.

After the paper is removed I use lacquer thinner to clean off residual

adhesive. When the thinner is evaporated, I put the new paper on.

It's not something I enjoy doing but it's necessary.

In normal use the blocks last about a month. It was even worse

when I had two different grits on each block. Eventually I made more

blocks so I could double-face them and change the paper less often. Note:

I don't make sanding blocks this way any more. The 1/2" MDF is so

inexpensive that it's actually less expensive to throw them away than it is

to clean old glue from them. Now I use

carpet tape to glue on the paper. |

Making Sanding Blocks

I cut my general use blocks from 1/2" MDF. After you cut your blocks,

sand them flat. The best way to flatten a block is to spray glue a

full sheet of sandpaper to a piece of glass and hone the block on it.

The MDF I use is already pretty flat so it only took a few seconds using 220

grit paper to make them perfect. Hit all

the corners with a sanding block to knock off the sharp edge and radius it very

slightly. The small radius (maybe 1/16") is important to ensure your

blocks don't gouge your work if you don't put it down perfectly flat and also

helps prevent the sandpaper from getting caught on a raised edge and tearing

from the face of the block (which ruins the block).

Sandpaper comes in 9" x 11" sheets. It is best if you size your blocks

to use the paper efficiently. Use a dull razor blade to cut the paper and

to trim it after it is glued to the block.

Spray Glue Method

Spray a light, even coat of spray glue on both the block and the paper.

Let the glue get tacky (about 30 seconds to a minute). Put the paper on

the block and then turn the block so that the paper side is down. Roll the

sanding block onto all its edges to ensure the paper isn't curled up at the

edge. This is why you radius the edge slightly.

Apply

pressure to the block or clamp it down for about 15 minutes. Trim off the

excess sandpaper all the way around.

I used a permanent marker on all four edges to indicate the grit on the

blocks so I can identify them easily. The lacquer thinner I use to clean

glue from the blocks also dissolves the marker unfortunately. You can

write directly on the sandpaper using a Sharpie marker and it won't come off but

if you stack the blocks you also can't tell which block is which without pulling

them all out.

By the way, on the

adhesives page, I mentioned that I use cheap spray glue for things like

making sanding blocks. That used to be true, but the paper kept coming

loose. Loose paper is annoying and can damage the work. I use 3M 77

spray adhesive now. It costs a lot more, but it doesn't come loose, so

it's worth it.

Carpet Tape Method

I made a framed tray to lay several blocks in side by side to tape several at

the same time. The tape is fairly expensive and it's not the right width

for some of my block sizes. If I made blocks individually I would be

trimming off a lot of excess tape and throwing it away.

Be sure the block is absolutely free of dust and crud. It should feel

smooth and flat. Anything between the block and the sandpaper ruins the

sanding block.

Lay down tape over the block and then burnish it down well using a squeegee

or something with a firm, straight edge. Cut your sandpaper slightly

oversize and lay it upside down on the workbench. Wipe any dust or crud

from the back of the paper.

Remove the backing from the tape and attach the block to the sandpaper.

Apply pressure for a minute to ensure a good bond. The best way to do

it is lay a blank sanding block on top and use a couple clamps. Hand

pressure is ok.

Trim excess paper and tape from the block by guiding an old single-edge razor

around it. This ruins the blade so don't use a good knife. I can get

about 20 blocks from an old razor. The corner of the blade rounds over but

it stays sharp enough to cut the paper cleanly.

Now roll the block on all its edges. Mark the block with the sandpaper

grit and it's ready to use.

|

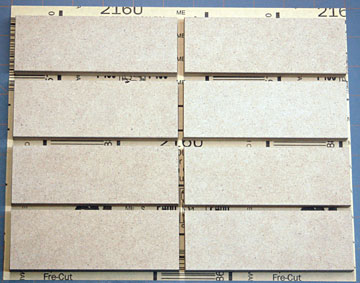

A standard sheet of sandpaper is 9" x 11". It is

best to size your sanding blocks to use the paper efficiently.

I suggest that you divide the sheet into individual sheets for one size

sanding block instead of cutting off one piece at a time.

Sometimes the pieces you cut won't have the grit marked on them so be

sure to write it on the backs as soon as you finish cutting the sheet

apart so you know what grit paper it is later. |

|

I'm currently experimenting with using double-sided carpet

tape to apply sandpaper to sanding blocks. The tape is 1-7/8" wide.

I made these blocks 1-7/8" x 5-1/4". Because I double face each block

with the same grade of paper I can cut eight sheets to make four sanding

blocks from one sheet of sandpaper. |

|

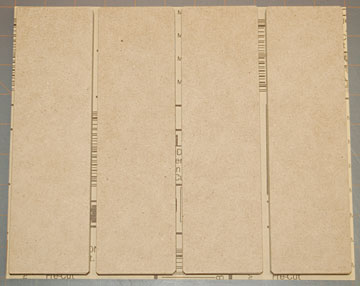

These blocks are 2-3/4" x 5-1/4". I can get six pieces

for 3 double-faced blocks from a standard sheet of sandpaper. |

|

These blocks are 2-1/2" x 8-3/4". I can get two

double-faced blocks from a sheet. |

Sanding Block Rack

|

This rack is very simple to make and helps keep your sanding

blocks organized. The reason I made mine is because I was stacking my

blocks on top of each other and every time they rubbed together it rubbed me

the wrong way. I wouldn't throw my good kitchen knives in a sink to

clatter together for the same reason — they need

to stay sharp. |

|

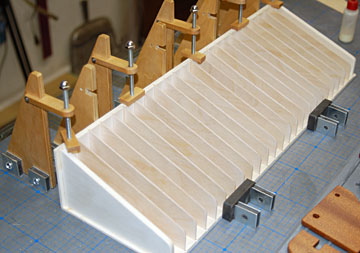

I glued a short stub of wood in my table saw sled and ran a piece of

1/4"

light ply through the saw. With each cut I moved the plywood over

so that the new groove was over the wood stub. That ensured identical

spacing. The edges were routed on my

router table. |

|

The bottom was glued on first using

carpenter's glue. It is held perpendicularish to the back by

propping it against

magnetic fixtures using film canisters filled with lead shot.

Vertical presses on the fixtures clamp the bottom firmly while the glue

dries. |

|

The dividers are cut from 1/16" aircraft ply and glued in the

grooves using carpenter's glue. When the glue had set up for a

little over a day, I applied several coats of Watco Danish Oil using a foam

brush. I used paper towels to remove excess after letting it set for

about 30 minutes. I applied two coats a day for three days.

I'm not real familiar with Danish Oil and it seems to take forever to

dry. My test has always been if I can smell the paint then it's still

releasing solvents and isn't fully dry yet. In this case that was a

couple weeks. |

|

The completed rack. Now I just need to find a place to

put it. If I knew in advance where it was going to go I would have

drilled holes to mount it before I glued it together. I may mount it

to a wall or on top of a bench. For the time being it's just going to

drift around the shop until I have a good place for it. In the

foreground are sheets of sandpaper pre-cut to fit the blocks I use. I

won't have to cut more paper for several months. |

|

![]()