Using Shear Webs

in Model Airplane Wings and Other Flight Surfaces

Imagine a stick of wood laying on your

workbench. If you hold each end and bend the stick some interesting things happen. On the outside of

the bend the wood is under tension. That simply means it is being

pulled apart. On the inside of the bend it is under

compression - it is being pushed together.

A pair of

spars behave in the same way.

If the wing is bent up, then the lower spar is under tension and the upper spar

is under compression.

It is normally the compressed spar that fails when a wing folds

Just because a wing fails does not necessarily mean the design is faulty. It could mean that the wing was stressed beyond its

intended limit or that the wing was poorly constructed. Just because a wing fails does not necessarily mean the design is faulty. It could mean that the wing was stressed beyond its

intended limit or that the wing was poorly constructed.

For example a

high

aspect ratio

sailplane wing could probably not survive a sharp pullout from a terminal

velocity dive. However, that does not mean the wing was not designed

properly.

Sailplanes

are not intended to perform this type of maneuver any more than your car

should be able to survive a high-speed impact with a brick wall.

On the other hand, sailplane wings have to be strong enough to withstand

High-G winch launches which requires careful engineering and construction.

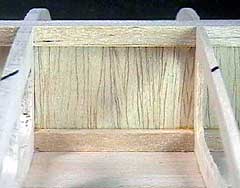

Shear webs essentially turn a pair of spars into

an I-beam. There is a reason why this shape is used

for construction

of buildings. It is light and strong. The webs add tremendous

strength to the wing construction and help prevent

a spar from compressing to the point of failure.

Some people mistakenly believe that a web glued

to the front or back of the spars is stronger than one between the spars due to additional gluing area. That

simply is not true. It is true that the glue joint probably will not fail,

but the wood can shear off under enough stress and the wing will mostly

likely fail soon after. Some people mistakenly believe that a web glued

to the front or back of the spars is stronger than one between the spars due to additional gluing area. That

simply is not true. It is true that the glue joint probably will not fail,

but the wood can shear off under enough stress and the wing will mostly

likely fail soon after.

However, most of our models are over-built and

shear webs placed on the front, back or middle of the spar will usually be

strong enough.

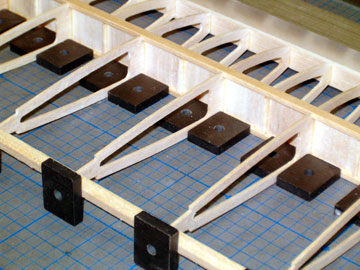

I always put webs between pairs of spars simply because I

know the webs are stronger as well as lighter (less wood and less glue).

Plus they look nicer under transparent coverings.

The grain of the web is vertical because that is

the direction the loads come from. I have seen designs that had webs

arranged with the grain running span-wise. That is absolutely wrong

and if you ever see this in a kit or on a plan, then make the webs with the

grain running vertically between spars.

Try this test: Cut a small square piece of

1/16" balsa wood. Put the piece between your thumb and middle finger with the

grain going from your thumb to your finger. Try to crush the balsa.

Turn the

piece 90°

and try to crush it. You can see that it is very difficult to crush

the wood against the grain. Shear webs use that property to great

advantage.

Note that webs do the greatest amount of good near the root of the wing.

If you use them in the first 1/3 of the span measured from the root towards

the tip, that will be good enough for most designs. Note that webs do the greatest amount of good near the root of the wing.

If you use them in the first 1/3 of the span measured from the root towards

the tip, that will be good enough for most designs.

I

tend to install shear webs along the entire wing span simply because webs weigh practically

nothing. Another thing I do is groove the spar to make installation

simpler. The groove isn't necessary but it helps keep the webs aligned as

well as hold them in place. I use my

Microlux table saw to cut the

groove to approximately 1/64" deep.

As far as I am concerned the webs are worth the

small amount of weight they add and the additional work necessary to

fabricate them. Therefore I use them in almost all of my models even

if the design does not call for them.

John Eaton kindly sent a link that explains the concept of spars and webs in more detail and is more accurate

information than posted here. Thanks John!

|

![]()