|

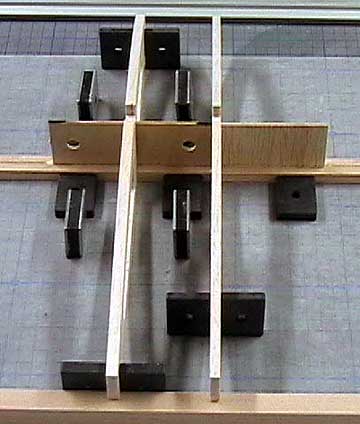

Use magnets without metal plates to

hold ribs in a vertical position. This is a task that was much more

tedious with pins. Arrange the magnets such that they attract to each

other and clamp the rib in between.

Adding the metal plates makes the magnets

much stronger and they are good for applying pressure when needed.

Ceramic magnets are very fragile and break easily — treat them gently.

|

|

Magnets are being used to hold three

laminations of 1/16" x 1/4" balsa to the balsa core. The magnets

without the plates are simply padding — scraps of wood could have been

used instead. The clamping pressure is being applied by the

magnets with the plates attached. |

|

These Fixtures

are wonderful. With each magnet having 12 lbs pull, these

fixtures stay firmly in place. The best way to remove the fixtures is to

tilt them sideways rather than trying to slide them off the board. |

|

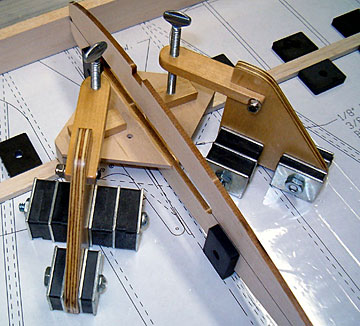

The

Vertical Press attachments are easy to make and greatly enhance the

functionality of the fixtures. The presses can lift the

fixtures from the board. I have a "monster" fixture having extra

magnets in the front so I can really crank down the presses when needed. |

|

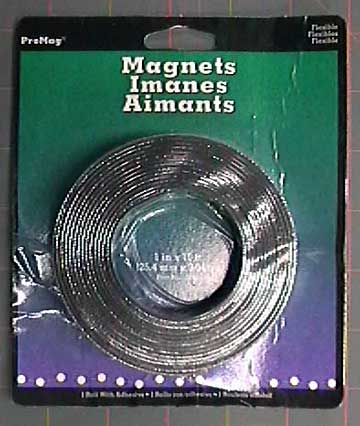

I found rolls of self-adhesive magnetic

strip in the craft section at Wal-Mart for less than $3.00.

They carry two different widths at the local store. You can also

purchase magnetic strip from the Magnet Source while you are placing your

order for the other magnets.

These strips can be attached to a variety of items that can be used with

your board. |

|

This aluminum extrusion now has a strip of magnet on it.

I frequently use straight edges to align parts as I lay them on the

board as shown

here and

here. |

|

The square extrusion on the right side of

this photo did not have the magnetic strip attached when this

photo was taken. It is being held in place by magnets to the right

of it.

Your local hardware store or places such

as Home Depot have a variety of extruded shapes to choose from. |

|

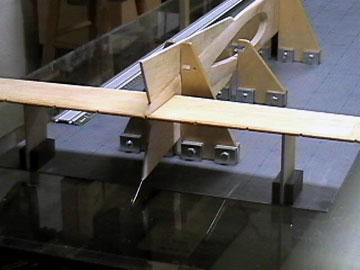

Use a few fixtures to hold the wing up for hinging.

The trailing edge of this wing is being

fiberglassed. A few scrap pieces of foam or a folded paper

towel between the fixtures and the wing will prevent any possible

damage. |

|

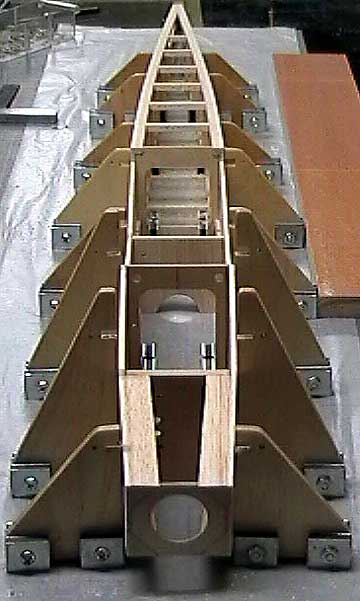

This is a

Doodlebug 330 Control Line model

designed by "Wild" Bill Netzeband. The profile fuselage is held

absolutely perpendicular to the board using strategically located

fixture pairs.

The horizontal stabilizer is being glued in place. To ensure it

is perpendicular to the fuselage, two scraps of balsa were taped

together and cut to the correct height to hold the stabilizer parallel

to the building board while the glued dried.

The balsa fixtures are held in place by a pair of magnets arranged

such that they attract to each other and clamp the balsa between them. |

|

An idea I came up with recently is magnetic wheel chocks.

On several occasions I've had the tail end of the fuselage roll off the

edge of the bench when I was working on the other end causing some nasty

hangar rash. |

|

These wheels can not move the chocks. When

significant enough force is applied, the wheels will eventually jump the

chocks. The chocks don't budge. Note that the wheel

chocks I make are taller than these (1" instead of 3/4") and have two

magnets per chock. |

|

For most model-building purposes, a fixture with four

magnets and a

vertical press will provide plenty of clamping pressure.

However, if you really want to crank it down, the front of the fixture

will lift from the board and all clamping power is lost. The

solution is easy — add more magnets to the

front of the fixture. All you need is a longer 10-24 bolt and more

magnets. |

|

Wayne O'Craig sent along this neat idea for a wing jig. Maybe this will help all those

folks who keep e-mailing me asking where they can get an

Ajusto-Jig. |

![]()