|

Silk is very easy to apply to solid areas. Often

there are tiny wrinkles that are easily stretched out. In many cases

a dark line remains where the wrinkle used to be. I wanted to

avoid that problem on the wing

servo hatches so I decide to apply the silk in a different manner.

Wet silk was applied to the frame, stretched and doped around the

perimeter.

This is the same frame I use to test various finishes. Most

coverings peel off easily. The frame is sanded and it's put away

until next time. |

|

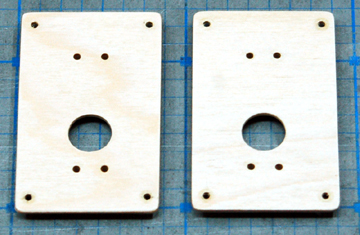

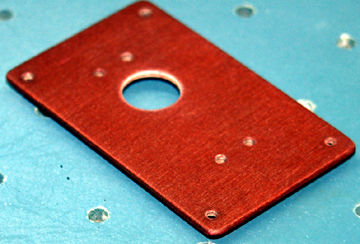

The

servo hatches were finished

sanded and sealed with several coats of dope on both sides.

All holes were well sealed because exhaust oil has a bad habit of

creeping everywhere. I really don't like

fuel-soaked model aircraft.

A couple pieces of light-duty

double-sided tape hold the hatches in place. |

|

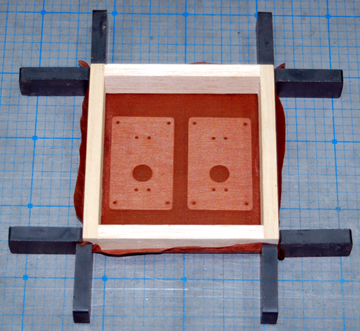

The frame is aligned over the hatches and held in

position using

magnets. |

|

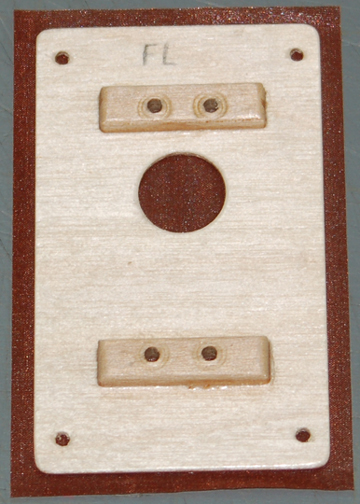

Brush on two coats of dope. Allow to dry

thoroughly. I used a sharp

razor to cut the silk around the inside perimeter of the frame while

everything was still clamped to the board. |

|

Use a

straightedge and a razor blade to trim the excess silk. Leave

enough to wrap around each edge. |

|

Wrap the silk around the hatch one edge at a time.

Apply dope to the exposed edge of the hatch and to the inside of the

silk to soften the dope already in the silk. Wrap the silk

around and rub it down with your finger. |

|

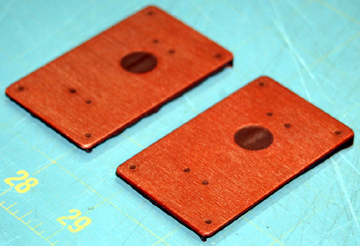

Excess silk was sanded away. I used a conical

sander in a

Dremel to open the holes to give them the neatest possible

appearance. The hatch is now ready for finish coats or sanding

sealer to fill the weave if opaque colors will be used. |

|

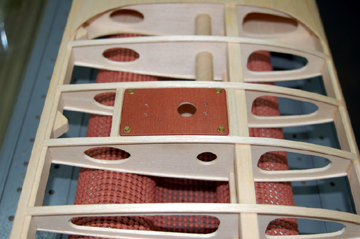

The silked hatch in the unfinished wing. |

![]()