About fiberglass base finishes

Mike James (NextCraft

composite guru) tells me that a fiberglass finish adds tremendous strength

to the finish by "unitizing" it.

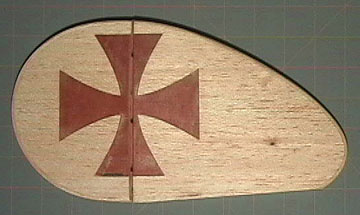

A fiberglassed component

A common misconception regarding a painted fiberglass finish is

weight.

A painted finish using fiberglass as a base is not heavy if it is applied correctly.

The only

purpose of the resin is to adhere the cloth. There is no reason to

apply heavy coats of resin. Applying a light coat and sanding between

each coat of the

finish will keep the finish thin and light.

The reason painted finishes have gotten a bad reputation is because some

people slop on the resin and then apply a second coat. A light

sanding is followed with a thick coat or three of primer. These are lightly sanded,

Bondo is added and then thick

coats of paint are applied.

A finish such as this is heavy and the

paint is likely to chip, peel or crack under flight stress and ground

handling. More likely the plane will become a hangar queen because

it is overweight. The perpetrator of this finish will carry on the fine

tradition of claiming paint is heavy. His paint jobs are

heavy, but yours don't have to be.

If you begin with good construction then you shouldn't have to use much filler

if at all.

This article will not discuss priming and painting. It will teach you

to apply a good, lightweight fiberglass base. What I am presenting is

the traditional technique for applying glass cloth.

Caution! Do not apply fiberglass

in extremely humid weather. Water will end up in the resin and it may

never

cure properly.

Resin can be applied in cold weather, but it will take a long time to fully

cure. It is best if you can put the component someplace relatively warm

while it cures.

|

![]()