|

The aft end of the fuselage is usually filled with

balsa

wood rather than diagonal pieces. The fill reinforces the tail

and it allows you to cut pushrod exits. If you didn't

have sheet wood surrounding the exits, you would have to cut holes in

unsupported covering. The covering would eventually begin to tear

away. You can use

thinner wood here if you arrange the grain vertically to act

as a

web. A lot of planes turn out tail heavy. Do

everything you can to make the tail strong while using as little

material as possible.

|

|

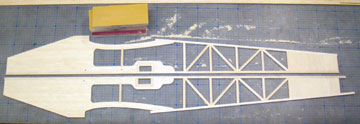

Most of the hard work is done. When this assembly

is dry, remove it from the board and build the other side. It is best if you can build the

second side directly over the first. Put a piece of wax paper

between the two sides and line the parts of the second side up

carefully.

You can pin directly through both sides into your building surface or

set up straightedges that are higher so that they enclose the outlines

of both sides.

Be sure to place the outsides of the fuselage sides together!

If you put an inside against an outside you will build two left or

two right sides which will not make you happy when you realize you have

to throw a lot of work away and build a new side.

|

|

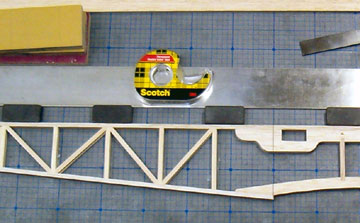

Block sand the inside of the fuselage sides now.

Keep sanding until all joints are flush. Go ahead and finish sand

because this is your last opportunity to do it.

This step is very important!

Remove the sanding dust and then apply strategically

placed double-stick tape to one fuselage side.

Carefully align the other side directly over the first. Check

to ensure the sides are aligned as well as they can be

— particularly

the wing saddles, firewall and tail. Pull the fuselage sides apart and stick

them back together until they're right.

Using a long sanding block, sand the sides to an exact match to

include the wing saddles if needed.

Check your work carefully because this step will save you from all

kinds of alignment problems later. |

|

Take

measurements from the plans and use landmarks in the construction to

draw the locations of all the formers and other items inside one

fuselage side while the sides are still taped together. Use a good

square to transfer the lines to the

outside edge. Use these lines to locate and draw former locations

inside the other fuselage side.

If the firewall has right thrust be sure to locate the lines

properly on each fuselage side because they will be in different

locations. |

|

Separate the two sides and then block sand the outside to

remove excess glue and to bring everything flush. The outsides

can be rough sanded because they will need additional sanding as you

progress with building the fuselage. |

|

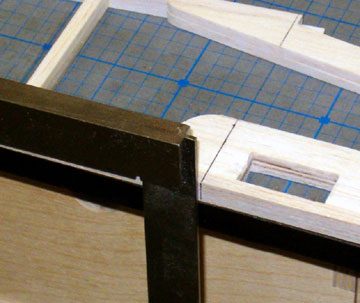

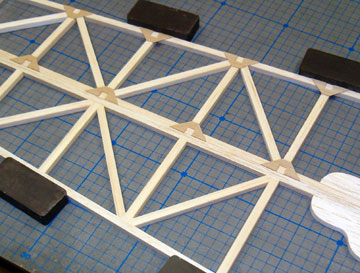

Many designs and kits leave out gussets.

However, I strongly urge you to use them. They weigh practically

nothing but greatly increase the strength of the brace joints.

If you choose not to use gussets then the only thing preventing the

braces from popping loose in a hard jolt is tension from the covering.

Note that gussets are glued to the inside of the fuselage sides.

The notch will capture the cross-braces.

I make gussets from 1/64" plywood which can be easily cut with

scissors.

Be sure to clean glue ooze from around the gusset and especially from inside

the notch where the cross-braces go. Blobs of glue will interfere

with the fit of cross-braces installed later.

|

|

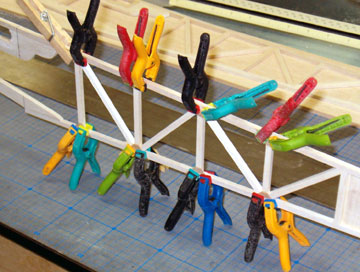

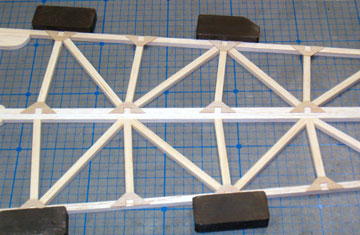

Clamp the gussets while the glue dries to ensure the

strongest possible glue joint. |

|

When the glue has dried place both sides on the board as

a mirror image. Take care aligning them. I put a stop at the

front and the tail post to keep the sides from moving. |

|

Glue the gussets on the second side aligning them with

the gussets on the first side. This will ensure that the

cross-braces are exactly perpendicular to the fuselage centerline in top

view. |

|

Flip the sides around and repeat the above steps.

Do not leave the sides together while the glue dries. The sides

will end up glued together by the glue that oozed out. Don't

forget to clamp the gussets while they dry. |

![]()